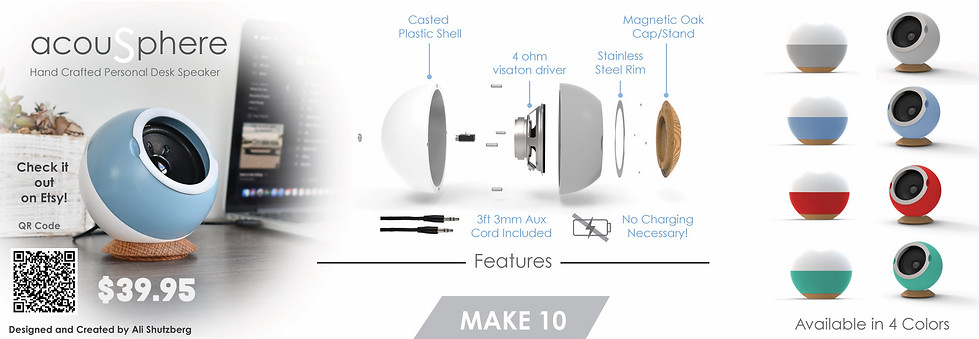

acouSphere

Spring 2020

Course Description

Make 10 is an industrial design course at Georgia Tech. The goal of the class is to challenge students to design a consumer product with a focus on manufacturability. We began the semester with thinking of a concept, which lead to...

detailing a final design, evaluating our material cost and setting a price, manufacturing 10 units (in 2 weeks), creating the brand, marketing the products on Etsy, and finally selling and distributing.

Project Description

Most handmade speakers are built into rectangular boxes, because it’s the simplest shape to construct. Ideally, the internal chamber behind a speaker is smooth with no hard corners. A sphere is a simple, smooth shape, so I challenged myself to construct a personal speaker in this form factor for Make 10 by learning how to cast a custom plastic design. By designing the wooden cap/stand strategically, I also employed the spherical surface to enable the speaker to swivel and face several directions, providing a direct audio experience.

Every piece of this product, besides the driver and connector, is handmade. I built custom molds to cast the plastic components. The oak caps were hand turned, finished, and engraved. The stainless steel rim was water jetted and sand blasted. I personally sanded, painted, wired out, and sealed each speaker.

I found that learning how to build a mold and casting plastic parts was the most enjoyable part of this process! There was a lot of work up front to create the mold properly, but it was worth it to manufacture high quality plastic parts so efficiently. It made all the difference in making acouSphere a premium quality product.

I listed the speakers on Etsy and sold all 10 in less than a week!

acouSphere - How it's Made

A complete product design, manufacturing, and marketing overview

Gallery